Vacuum Casting

Do you need production quality plastic prototypes fast? Polyurethane vacuum casting may be the ideal solution for you. TIPTOP is fully capable of handling your vacuum casting and silicone molding needs. And of course all of your parts are expertly finished with professional painting, printing and machining.

Vacuum casting is a great method to make rigid or flexible parts, and is ideal for high quality prototypes, function testing, concept proofing and display demos. Urethane casting parts can be made from a few to hundreds as required.

Contact us today for more information about our casting services.

What Is Vacuum Casting?

Using the product prototype, transparent or opaque small batch samples with different properties such as ABS, PP, PMMA or rubber are made through silica gel mold and vacuum pouring process. The reproduction of transparent parts and soft rubber parts is like injection molding and rubber products, and the metal insert process is irreplaceable by other hand board manufacturing processes. The materials used mainly include transparent PU, soft adhesive PU, PU similar to ABS and PP, which can modulate replicas of different colors.

Advantages Of Vacuum Casting

★ Fast turnaround

★ Low cost for molds

★ Many kinds of PU,could overmolding and insert

★ Can accurate copy many different texture

★ Molds are durable for 20 or more copies

★ Capable of producing large parts

★ Coloring pigments can be added to the resin

Vacuum Casting Process

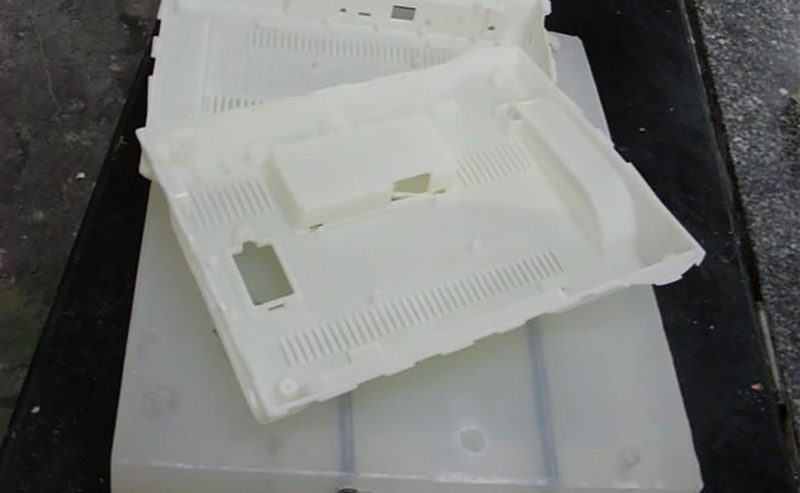

Step 1. Master Patterns

Patterns are 3D of your designs, usually made by CNC machining or SLA/SLS. Patterns need to be able to withstand heating to 40°C. After finish and inspect the masters, we will move to silicone mold making.

Step 2. Making the Molds

Casting molds are made from liquid silicone. Half-Fill the casting box with liquid silicone, Heat the casting box until silicone is fully cured and then allowed to cure in an oven for 16 hours. Fill with extra silicone liquid which is also heated & cured. Once dried, the mold is cut open and the master removed.

Step 3. Casting Copies

Poured the casting resins into the empty cavity to create a highly accurate copy of the original. Silicone molds are typically good for 20 or so copies of the master pattern.